Contact Info

133 East Esplanade Ave, North Vancouver, Canada

Expansive data I/O tools

Extensive data management tools

Dataset analysis tools

Extensive data management tools

Data generation tools to increase yields

Top of the line hardware available 24/7

AIEX Deep Learning platform provides you with all the tools necessary for a complete Deep Learning workflow. Everything from data management tools to model traininng and finally deploying the trained models. You can easily transform your visual inspections using the trained models and save on tima and money, increase accuracy and speed.

High-end hardware for real-time 24/7 inferences

transformation in automotive industry

Discover how AI is helping shape the future

Cutting edge, 24/7 on premise inspections

See how AI helps us build safer workspaces

The 4.0th industry revolution aims to develop smart factories which employ the Internet of Things (IoT) as well as Artificial Intelligence (AI). In the metal industry, predicting product quality in real-time and giving specific feedback on the type, size, shape, and location of each defect are crucial tasks, which can be best achieved with the help of an intelligent machine that takes care of automatic defect detection and data quantification. Defect recognition and classification can be performed by supervised and even unsupervised deep learning techniques.

Dr. Jong Pil Yun from Korea Institute of Industrial Technology, Republic of Korea, and his colleagues have recently researched the applicability of machine vision in detecting metal surface defects. As mentioned in their paper published in the journal of Manufacturing Systems, though Deep Convolutional Neural Networks (DCNNs) are being successfully used in manufacturing industries for defect recognition and classification, they suffer from the lack of large training datasets due to the difficulty of gathering such data. Using small training datasets or poor-quality ones results in an overfitted classification model or poor generalization performance. To tackle this problem, data scientists turn to data augmentation techniques. Some conventional methods to generate image data through label-preserving linear transformations include translating, rotating, scaling, blurring, changing contrast, flipping, shear mapping, adding noise, sharpening, and so on. However, these techniques will only create image-level transformations through scale and depth and would do little to nothing in dividing boundaries between data manifolds. In addition, this kind of augmented data cannot enhance data distributions which are determined by higher-level features.

Yun et al. proposed a novel convolutional variational autoencoder (CVAE) and deep CNN-based defect classification algorithm to address this issue. Indeed, a conditional CVAE algorithm can generate adequate data for each defect type in a single CVAE model to train the classification model. Then, by using DCNN models with high generalization performance they can classify all defects. To verify their model, they applied the trained model to images obtained from an actual metal production line and proved that the model works well.

“A defect inspection system that detects defects in real-time and classifies defect types, is one of the key technologies required for the implementation of the smart factory ”

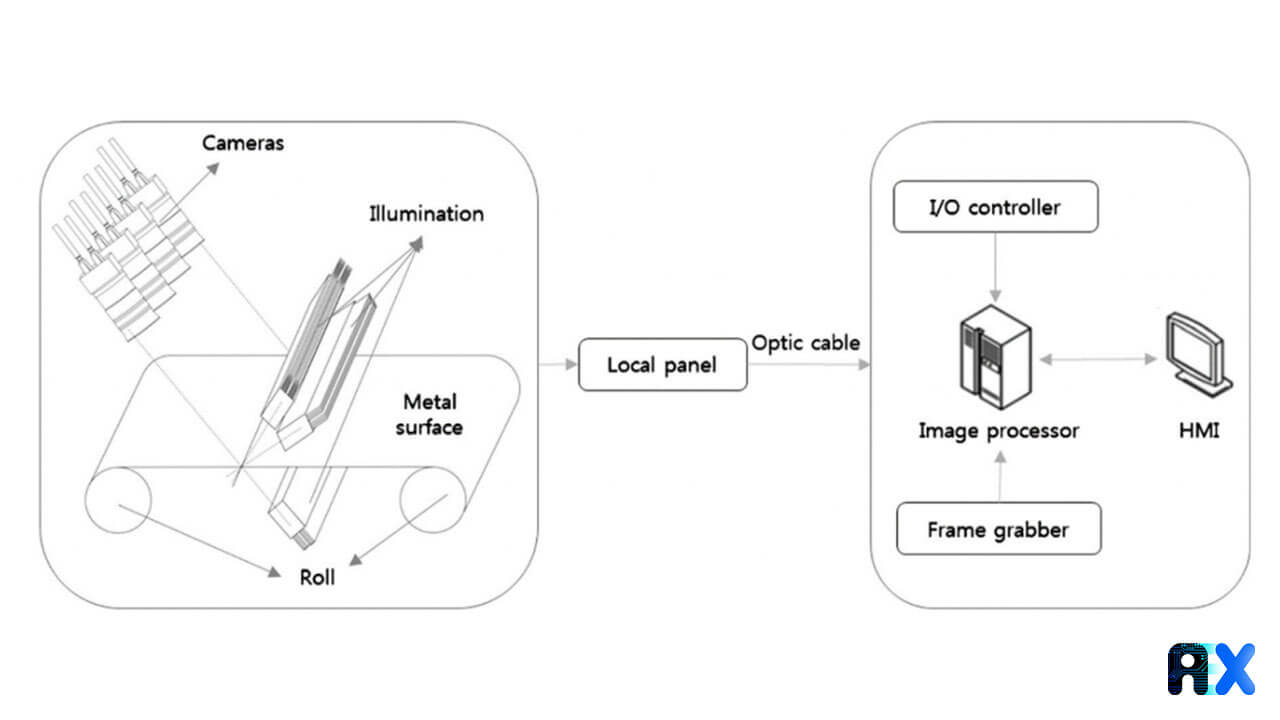

Figure 1 illustrates the overall workflow to inspect the surface of moving metal products. A line scan camera with a resolution of 12288 pixels in the width direction of the object was used along with an illumination bar. The image obtained from the line scan camera is sent to the image processing PC through the frame grabber. Then, the defect classifier model containing a data generation module and a defect classification module analyzes real-time incoming images, detects and classifies defects, and stores the results in a database. Six different types of metal surface defects, displayed in Figure 2, were chosen to train the model. After generating an adequate amount of data, 657 samples were used for training and 655 samples for testing the deep learning classification model. The trained model is then loaded on the inspection system to detect and classify metal surface defects in real-time. Finally, the results are displayed on the human-machine interface (HMI) screen, and defects’ information is provided to the operator.

“When developing an automatic defect classification algorithm based on a data-driven approach, it is important to have the same and sufficient amount of data for each defect ”

Training a deep-learning model with a small data set only works well for given data. In fact, it results in an overfitted model with a drastically reduced accuracy rate. In the proposed method by Yun et al. image augmentation is performed by a variational autoencoder, which creates images by automatically learning from the distributed data, then a high-performance CNN-based defect classifier model processes the generated images.

The VAE model is a directed graphical model with certain types of latent variables, such as Gaussian latent variables. The VAE model includes an encoder that extracts features from inputs and expresses latent variables, a decoder that generates an image from the latent variables, and a sampling module that generates the latent variable by sampling the output of the encoder. The encoder and decoder of the VAE model use deep neural networks.

Finally, the authors propose a CNN-based deep learning model to classify defects i.e. the conditional CVAE (CCVAE). The classification model also contains four feature extraction layers and a classification layer

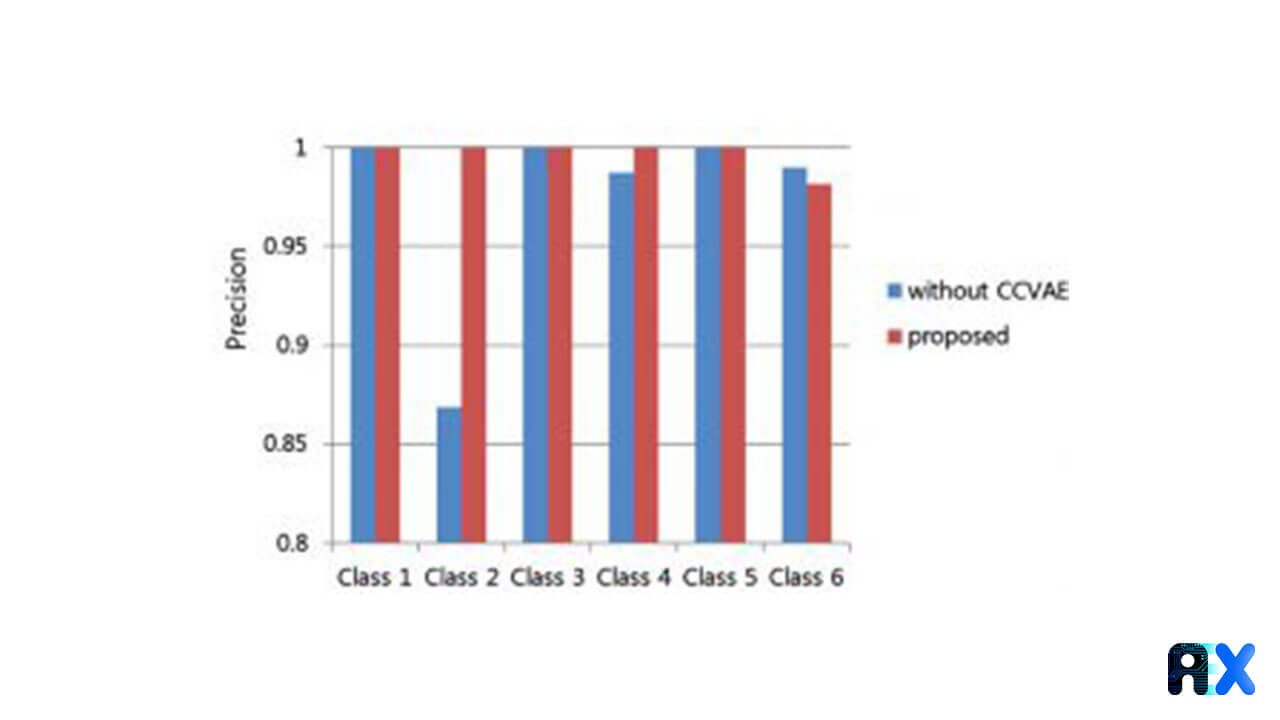

Figure 3 shows the precision of the defect classification model w/wo using the proposed CCVAE model. The precision of the model is relatively poor when trained without CCVAE, due to the lack of sufficient data and an imbalance in existing data. However, using the data augmentation method by CCVAE, the model’s precision was considerably improved for all classes, thanks to a large amount of data. Hence, the defect classification system proposed by Yun et al. exhibited excellent performance when used for actual metal surface defects detection with imbalanced data.

You can enter your email address and subscribe to our newsletter and get the latest practical content. You can enter your email address and subscribe to our newsletter.

© 2022 Aiex.ai All Rights Reserved.