Contact Info

133 East Esplanade Ave, North Vancouver, Canada

Expansive data I/O tools

Extensive data management tools

Dataset analysis tools

Extensive data management tools

Data generation tools to increase yields

Top of the line hardware available 24/7

AIEX Deep Learning platform provides you with all the tools necessary for a complete Deep Learning workflow. Everything from data management tools to model traininng and finally deploying the trained models. You can easily transform your visual inspections using the trained models and save on tima and money, increase accuracy and speed.

High-end hardware for real-time 24/7 inferences

transformation in automotive industry

Discover how AI is helping shape the future

Cutting edge, 24/7 on premise inspections

See how AI helps us build safer workspaces

Brake systems are one of the most critical components of a vehicle, as they ensure safety by stopping the car and preventing accidents. It is essential to prevent low-quality brake pads from entering the market to ensure reliability and maintain performance over time.

In this blog, we will explore how AI is being utilized for the quality control of brake pads. By utilizing deep learning and image processing, defects in brake pads can be quickly and accurately identified and defective items removed from the production line. The ultimate goal is to assist businesses in meeting consumer demands for high-quality products.

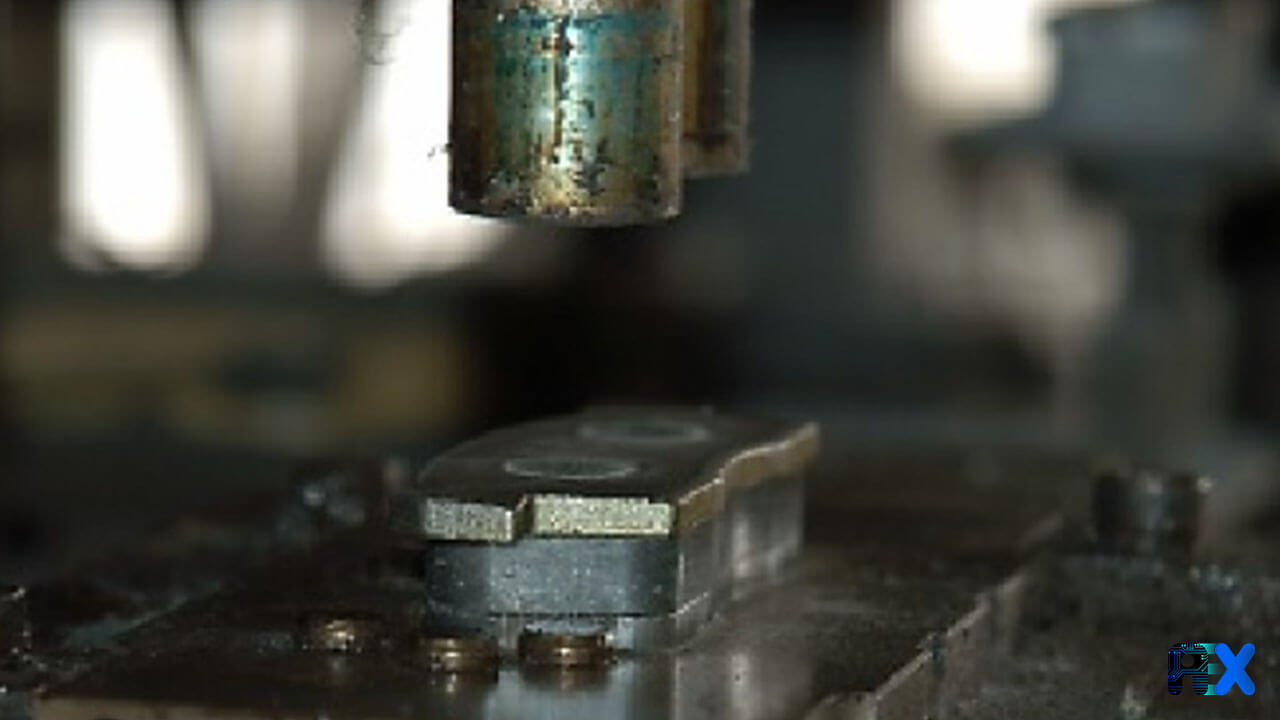

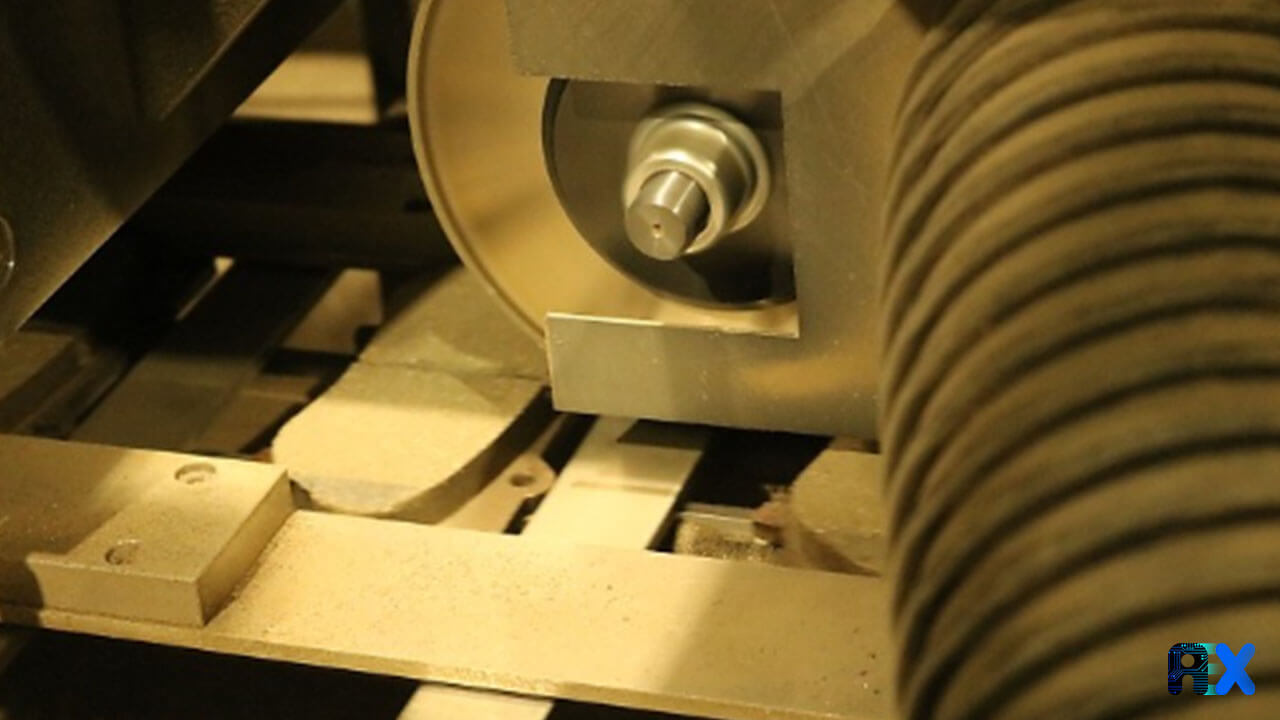

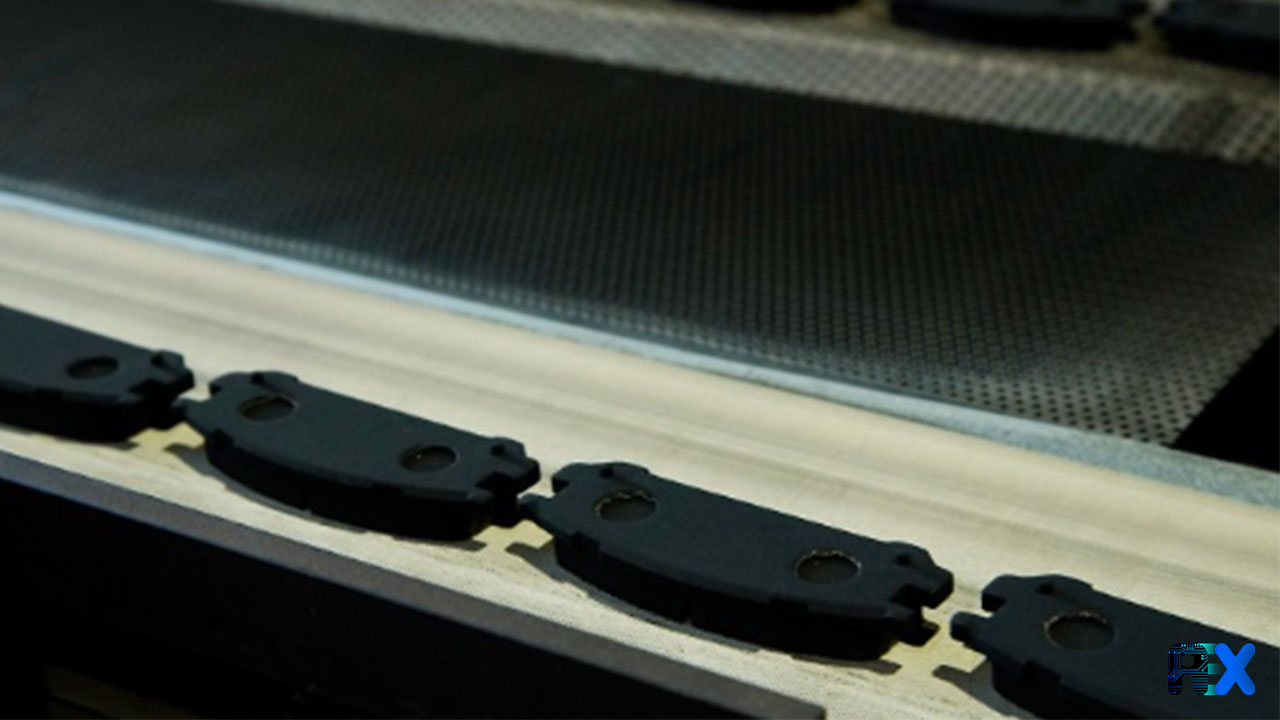

The brake pad is one of the most challenging components of a vehicle to engineer and produce. Let’s review its manufacturing process.

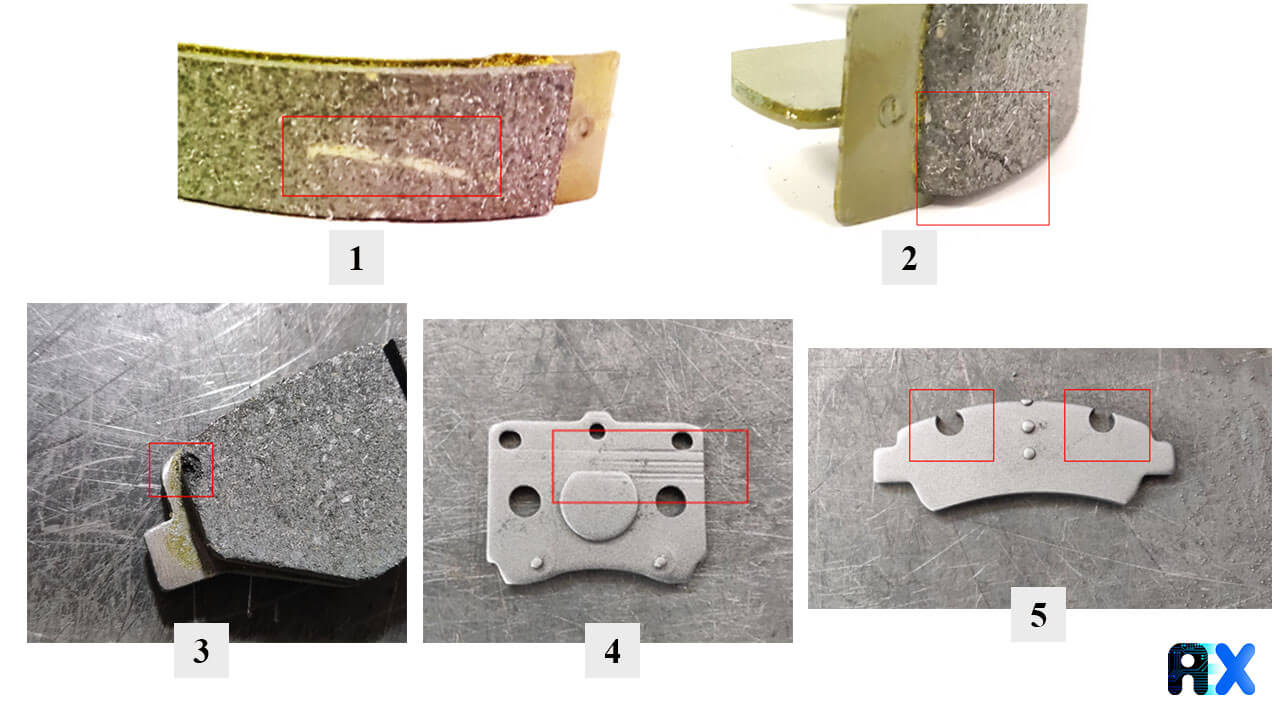

During the manufacturing process, several defects can occur such as impurities in the friction materials, cracks in the friction material:

Ensuring that defective products are quickly identified and removed from the production line is a crucial responsibility for any factory. However, traditional methods of quality control, which rely on human labor, can be both time-consuming and costly. With the advent of artificial intelligence, the quality control process can now be completed with greater speed and accuracy. AI-based systems can quickly and efficiently identify defects in brake pads, reducing the need for manual inspection and minimizing the risk of defective products reaching the consumer.

Artificial intelligence has revolutionized the industry, providing new opportunities for flexible and efficient production, even when it comes to complex and customized products.

Manufacturers are now using smart cameras and AI models to enhance their quality inspection processes compared to traditional methods.

Image processing methods include:

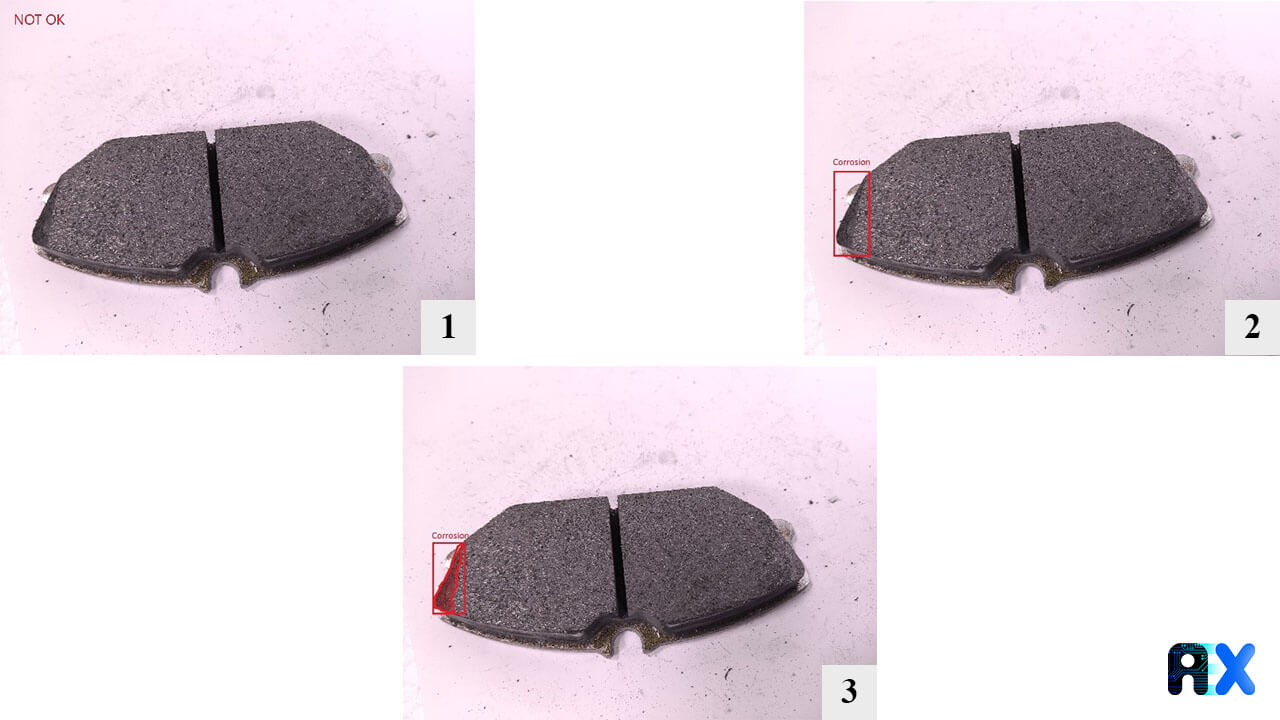

This model aims to specify the class of each entity, for example, classifying defects into categories such as minor defects, major defects, or OK and NOT OK.

An object detection model finds objects in an image and specifies their location with a bounding box, they can be used to detect features such as detecting cracks or corrosion in brake pads.

A segmentation model aims to specify the object in a more precise way by selecting the pixels containing the object.

The AIEX platform provides all the necessary tools to train models for classification, object detection, and segmentation.

Please reach out to us if you need more information.

AIEX is an industry solution platform created by computer vision (CV) experts and powered by deep learning aiming to provide cutting-edge solutions to various industries.

Image processing and deep learning have revolutionized the quality control process, allowing for quick and accurate detection of defects in any part of the production line. The rate of defect detection with deep learning solutions is significantly higher than that of human inspection.

AI-based methods can be used to identify defects in a wide range of products, reducing the need for human intervention and automating and optimizing quality processes. Businesses can leverage these technologies to increase productivity, cut expenses, reduce waste, and enhance customer satisfaction.

[1] https://www.powertech-auto.com/how-brake-pad-manufactured-process/

[2] https://www.mk-kashiyama.com/en/brake-tips/manufacturing-process

[3] https://machinelearningmastery.com/object-recognition-with-deep-learning/

[4] https://postindustria.com/how-ai-for-quality-control-enhances-yield-in-ml-manufacturing/

You can enter your email address and subscribe to our newsletter and get the latest practical content. You can enter your email address and subscribe to our newsletter.

© 2022 Aiex.ai All Rights Reserved.