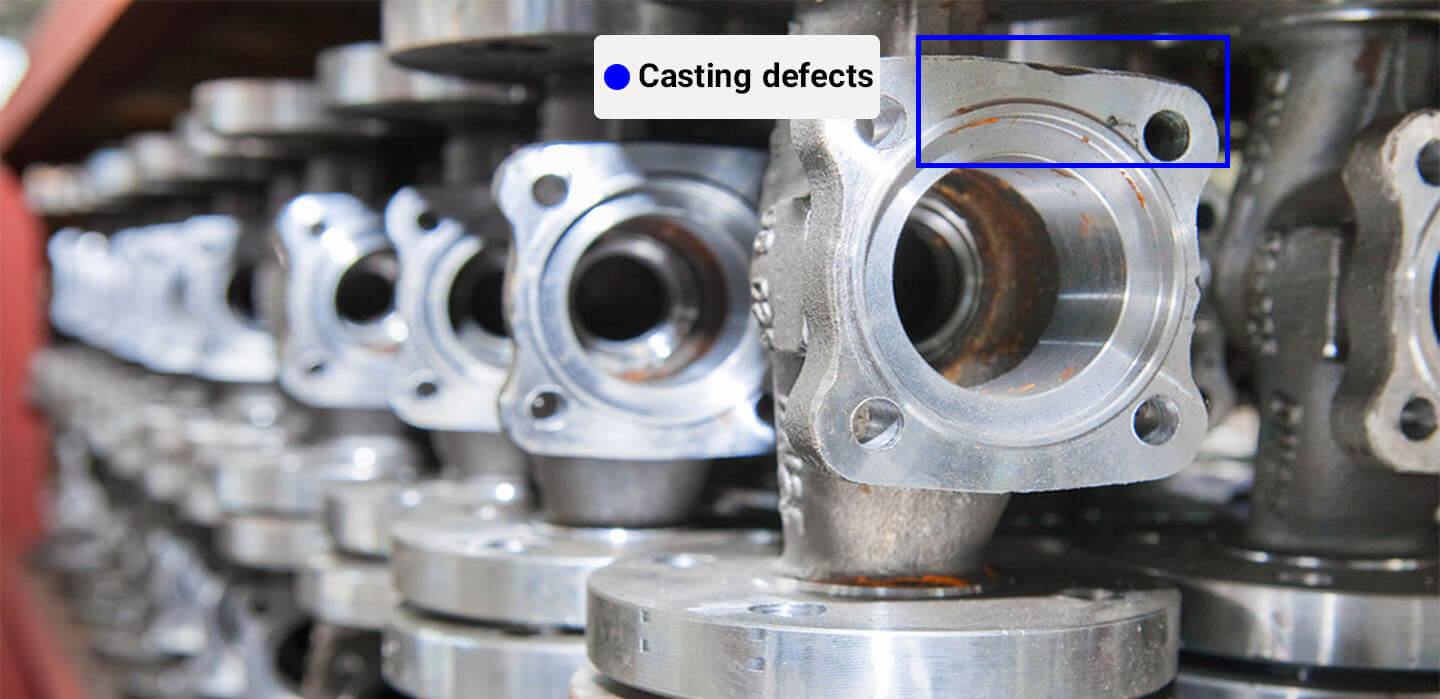

Tag: casting defects

-

Intelligent Defect Detection in Metal Parts using Optical System for Industry 4.0 Manufacturing

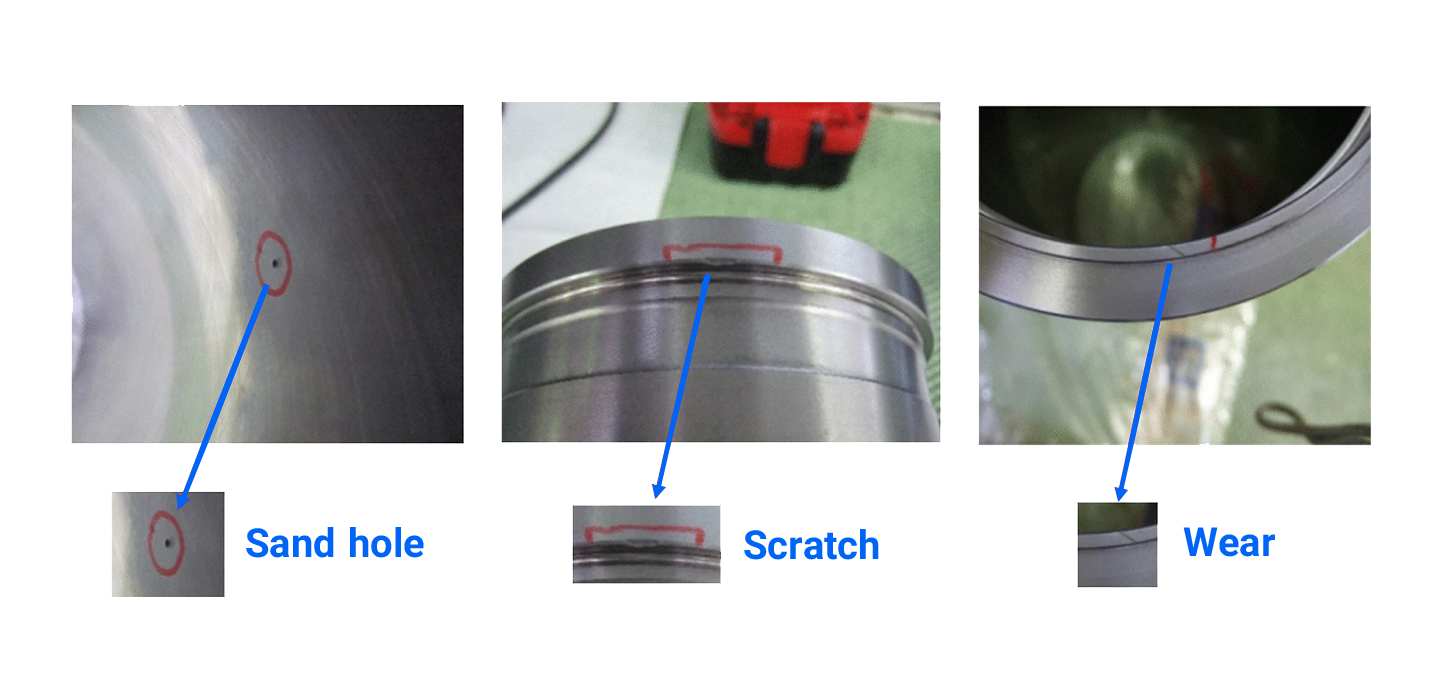

Detecting and classifying aesthetic defects in different sizes, shapes, and positions immediately after the casting process is an essential task for the quality control unit. In this paper, we introduce a simple, low-cost, and efficient optical system powered by deep learning models to quickly, accurately, and automatically identify and classify casting defects.

-

Aluminum casting quality control using computer vision techniques

Automated X-ray systems are improving quality through multiple objective inspections, and reducing labor costs, and increasing productivity and consistency by revising involved processes. This paper proposes a novel approach to train a YOLO-based model for detecting defects in aluminum castings. Deep learning-based models are garnering more attention in the aluminum castings industry every day, and…