Contact Info

133 East Esplanade Ave, North Vancouver, Canada

Expansive data I/O tools

Extensive data management tools

Dataset analysis tools

Extensive data management tools

Data generation tools to increase yields

Top of the line hardware available 24/7

AIEX Deep Learning platform provides you with all the tools necessary for a complete Deep Learning workflow. Everything from data management tools to model traininng and finally deploying the trained models. You can easily transform your visual inspections using the trained models and save on tima and money, increase accuracy and speed.

High-end hardware for real-time 24/7 inferences

transformation in automotive industry

Discover how AI is helping shape the future

Cutting edge, 24/7 on premise inspections

See how AI helps us build safer workspaces

When it comes to manufacturing, quality control has always been an essential and costly task. The biggest problem for producers is that even a slight variation in production processes or materials can make the entire production function defective.

The advantages of detecting defects before they leave the manufacturing facility are clear. But, humans need extensive training to perform visual inspections and are prone to distraction and fatigue, that can result in grave and costly mistakes. Thus, these inspections can create bottlenecks in production and cause delays.

Defect detection can be automated by technologies such as Computer Vision, a subset of artificial intelligence (AI). Computer-based vision systems specialized in defect detection are more affordable than defect detection personnel and more accurate in detection and reporting.

Computer vision is a subfield of artificial intelligence and machine learning, which can process, analyze, and make sense of visual data (images or videos) like humans do.

In the past few years, we have been able to use computer vision and image processing (video processing) in industries such as automobiles, health, food, etc. to do things faster and more accurately.

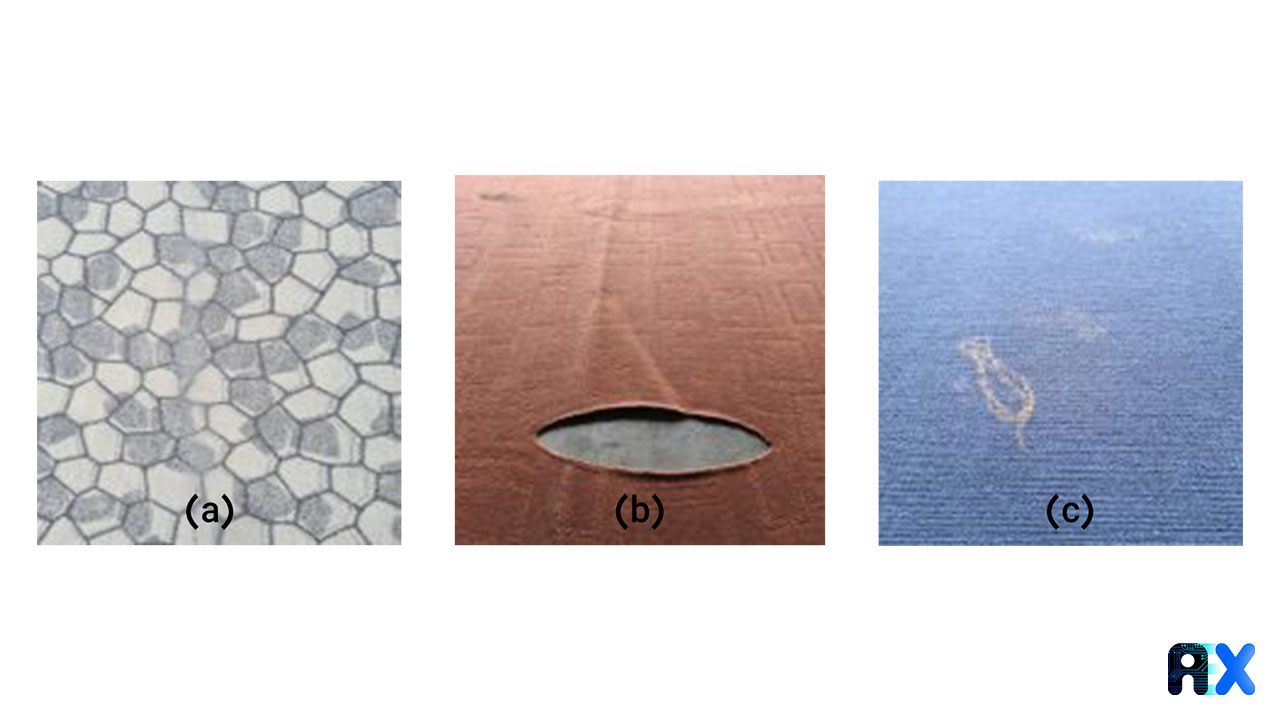

Carpet is a type of flooring made from weaved fibers. Carpets come in a variety of styles, patterns, and colors. A carpet defect is an imperfection on the surface of the carpet caused by the manufacturing process. Different imperfections can appear on the outer layer of texture because of yarn defects, improper operation, and over-stretching. If there are defects in the carpet, the price is affected. Thus, carpet imperfection identification is a fundamental step for quality control in textile manufacturing. Figure 1 shows a few types of common defects.

The traditional method is based on time-consuming visual inspection by humans, which can result in inspectors inadvertently missing some defective products.

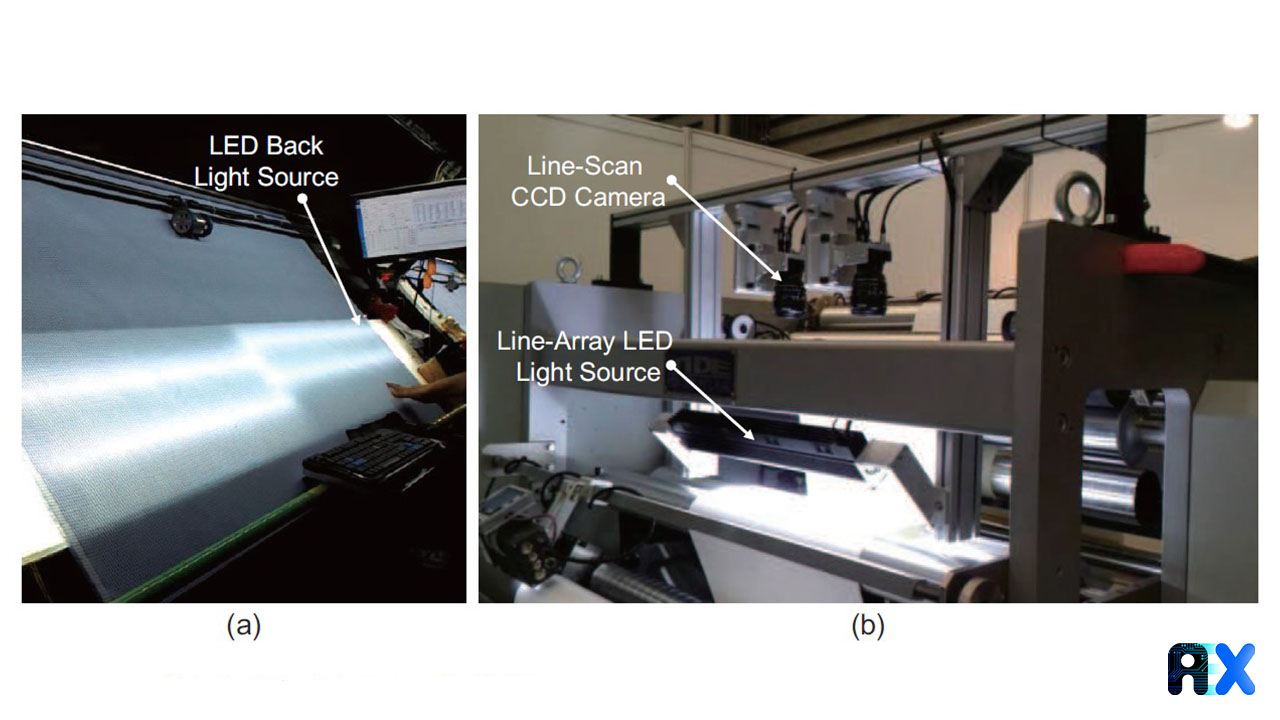

In recent years, with the help of digital image processing techniques and computer vision, automated fabric defect inspection has become popular and has gradually replaced the traditional method. Cameras are used to inspect carpets during production, and computer vision techniques look for defects in the products and report them. (Figure 2)

To use computer vision to detect defects in the carpet industry, it is necessary to perform the following steps:

1- Collect sample pictures of defects

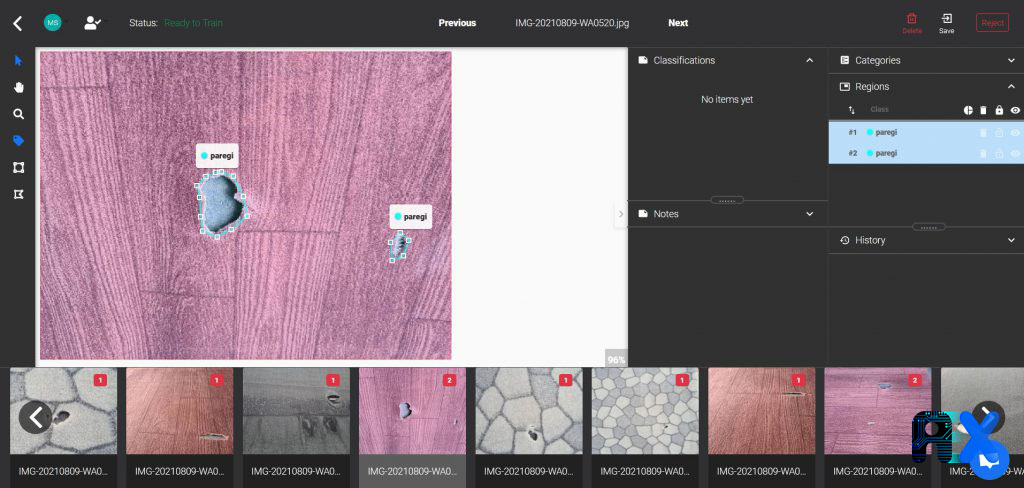

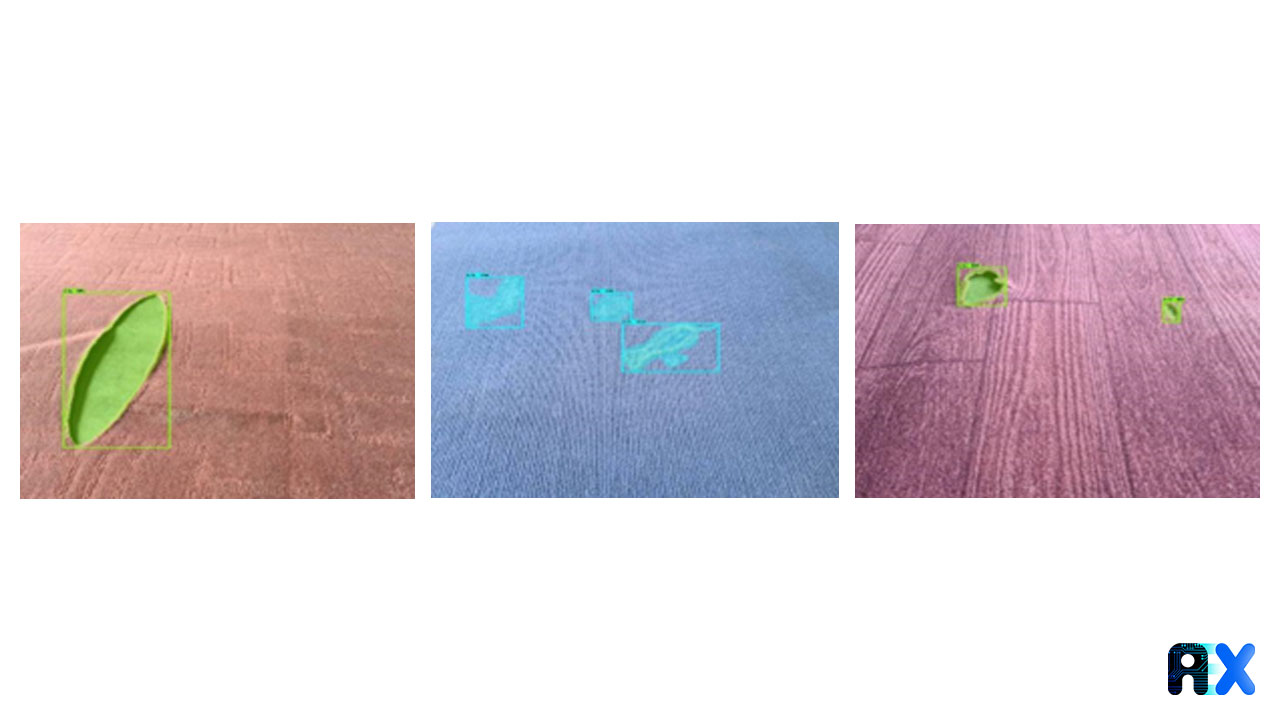

2- Identify and label all the defects on the images (Figure 3), A process known as annotating

3- Train the model with collected sample defects

At this stage, we have a computer vision model capable of identifying, categorizing, and reporting fabric defects automatically.

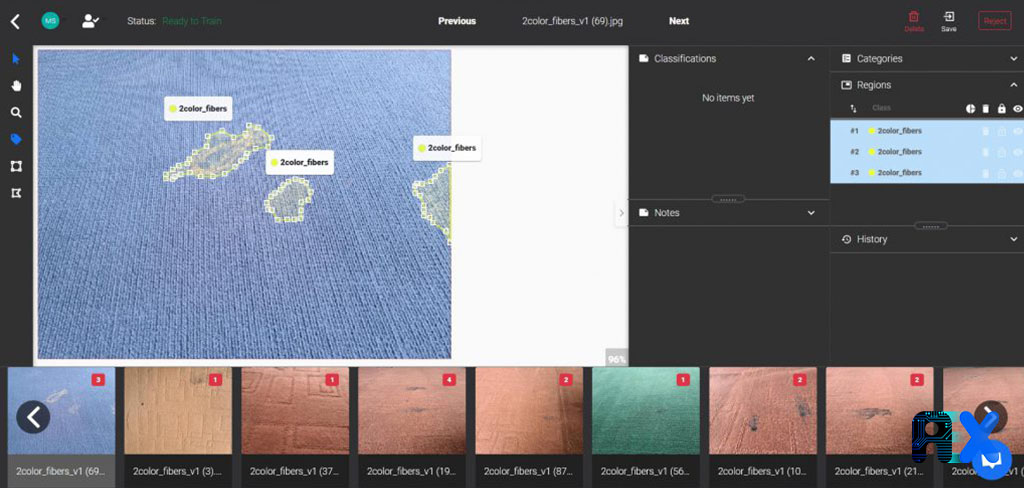

Figure 3. annotating carpet defect (a) hole defect (b) color defect

For this project, we will use the AIEX platform to obtain the desired computer vision model. First, we upload all the sample images of carpet defects to our new project, then we annotate them one by one to indicate what the model should look for. The last step is to choose the type of training we want to use and start training our model. After training concluded, we have a model ready to detect carpet defects. We can test it by feeding the model with new images and inspecting the outcome (Figure 4).

Manual inspection of product quality is a time-consuming task that increases production costs and material waste. With computer vision-based defect detection techniques that automate and optimize quality inspection processes, businesses can achieve higher efficiency, lower cost, minimal waste, and greater customer satisfaction.

You can enter your email address and subscribe to our newsletter and get the latest practical content. You can enter your email address and subscribe to our newsletter.

© 2022 Aiex.ai All Rights Reserved.